SLITTING FILM

Since many film types were only available from the film manufacturers

in 35mm, 120, 65mm or 70mm stock, several submini camera manufacturers designed

film splitters to allow cutting a smaller strip of film from larger stock.

With a film slitter, you can get some amazing film into your submini, such

as 2475 recording film, B&W or color infrared film, Tech pan, Agfapan

25 and Ektar 25. Sometimes called film splitters -- and NOT to be confused

with film SPLICERS -- these devices came in various styles to cut different

size strips. Some cut a 35mm strip in half to produce two 17.5mm strips for

cameras that used that size film. Others would cut 16mm strips, 9.5mm strips

and even 8mm strips. Some of the companies that made these slitters were

GaMi, Minolta, Yashica, Ricoh, Mikroma, Microtec, Acmel, and Varitype. There

are undoubtedly more. They basically work the same way. Using razor blades,

of some type, they cut out smaller strips of film from larger. These items

are no longer being made and are very difficult to find.

But, if you want a ready-made slitter, we suggest you check out:

They offer a wide variety of film slitters to cut 70mm, 65mm, 120, 35mm,

and 16mm films down to smaller sizes -- 127, 828, 35mm, #00, 126, 46mm, 21mm,

16mm, 17.5mm, HIT, Minox, 8mm, and more! -- in variaous configurations.

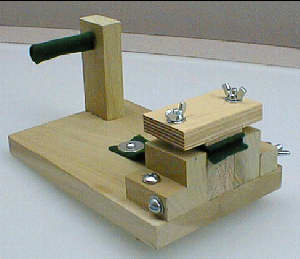

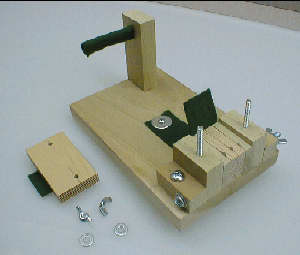

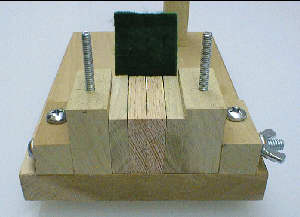

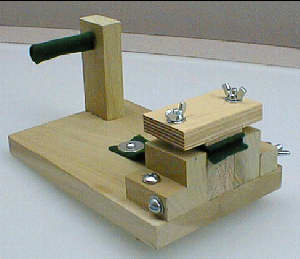

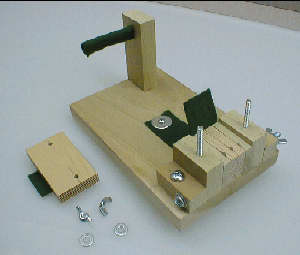

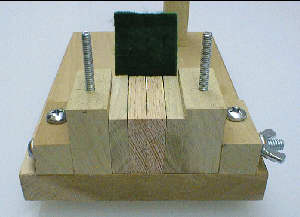

If you are handy or determined, you might even want to built your own slitter.

All you need are a few small pieces of wood, a couple of razor blades, some

basic tools, a little ingenuity and time. Here are some pictures of

a completed splitter. With this slitter, you place a bulk roll of 35mm film

on the part that looks like a black handle. The film is pressed down onto

the cutting block and a removeable pressure plate is screwed on top. Then

the film is pulled through the slitter and rolled up on the other side. Two

pieces of felt on either side of the film keep it from getting scratched.

You can use various materials in the construction of your slitter. The

decision on material is up to you. Wood is normally easier to work

with if you just have standard tools, but other materials may offer advantages,

if you are familiar with them and have the necessary tools. In building

your own slitter, one big problem you will come across is that the film is

measured in millimeters, but American building materials are normally cut

in inches. To complicate matters even more, when you add in the razor blades

inbetween the wood blocks, the width is increased very slighly, but it can

be enough to through off careful measurements. Here are some helpful

measurements:

-

3/8" wood = .375 inches = 9.525mm -- A piece of wood this thick will need

to be sanded down somewhat to produce the size of the Minox film (9.2mm).

-

5/8" wood = .625 inches = 15.875mm -- A piece of wood this thick (plus the

added thickness of the razor blade) should be just right for 16mm film.

-

11/16" wood = .6875 inches = 17.4625mm -- A piece of wood this thick (plus

the added thickness of the razor blade) should be just right for 17.5mm film.

-

1 3/8" wood = 1.375 inches = 34.925mm -- Pieces of wood that total to this

thickness (plus the added thicknesses of the razor blades) should be just

right for the total width of the 35mm film.

If you need just a little extra spacing, pieces of construction paper will

probably work fine. If you need a little less spacing, sand down the

wood with fine sand paper, measuring as you go.

Here are a few diagrams to use depending on the type and size of film you

plan to slit. The diagrams are NOT to scale.

If you are using 35mm unperforated

film.

If you are using standard 35mm perforated

film.

If you are using 16mm film, regardless of

the perforations.

You can see from these diagrams is that if you only use one size of film

to slit from (ex. 35mm) and one size of film to slit to (ex. 16mm) your job

will be easier. If you plan on slitting from different film sizes (ex.

35mm AND 16mm), or slit to different film sizes (ex. 16mm AND 9.5mm) your

work is more involved. You will need to make different film slitters

or make a slitter with different slitting block pieces. It's up to

you to decide which is the best route to take.

Before you get started, here are few points to ponder.

Making a slitter takes time even if you are familiar with hand tools. The

measurements must be precise and the pieces of material are small, making

cutting difficult. It also makes it easy to cut yourself, so watch

out!

The more planning you do up front the better your results will be and the

easier the job will be. The plans outlined here are generic plans and

need to be modified depending on the type of film you plan to slit, the type

of film you want to produce, the type of materials you plan to use and the

features you want to built into the slitter. You will first need to

spend time designing your slitter using these diagrams as a starting point.

If you have trouble designing your slitter, it's best not to build

one yourself.

The amount of wood used in the project is very small. Becasue of this

you can probably afford to move up from a soft wood, like pine, to a harder

wood, like oak. Your slitter will last longer, but your saws and drill

bits won't. Harder woods are trickier to work with.

The SUBCLUB can assume no responsibility for the success of your splitter,

nor for any damage you do to yourself or your camera during its construction

or use. In other words, you're on your own. If you have the

slightest doubt about building a slitter, you probably shouldn't built one.

If you are working with wood, the tools you will need are:

-

electric drill and bits

-

screwdriver

-

hammer

-

sander and sandpaper

-

wood glue

-

C-clamps

-

saw

-

pliers

-

ruler

-

pencil

The materials you will need will vary depending on size of the slitter you

make and the design and features you build into it.

-

wood (see diagram to design and measure your own pieces)

-

screws (flat head will probably work best)

-

bolts (there are several kinds available)

-

wing nuts (to go with the bolts)

-

washers (to go under the wing nuts)

-

felt (available at any fabric store)

-

dowels (depending on your plans)

-

razor blades (many types are available)

If your are a Minox user, you can see some

great plans

on this site.

And here's another site

with some super ideas for a slitter.

Whether or not you are a Minox user, here are some

generic plans with instructions and diagrams for

the slitter in the pictures at the top of this page.

This guy has figured out how to

turn a cheap

35mm camera into a film slitter.

If you have any ideas, suggestions or comments about these pages, please

contact the Sub Club at the FRONT

DESK.

To return to the main index for the Sub Club click

here.

COPYRIGHT @ 1995-2023 by Joe McGloin. All

Rights Reserved.